The first bit I tried was a Freud Matched Rail and Stile Bit which was an all in one bit see the link here to see what I mean . It's meant to run stiles through on one setting and then adjust the bit to run the ends of your rails after raising or lowering the bit. I couldn't figure it out the first time out so after messing with this for an hour or so I decided to abort and try the rocker matched bits.

Here are some pics of the bits I had from Rockler

After watching a few other blog posts and videos on the interwebs I decided a little pre-planning and preping for future cuts would be ideal here. Shout out to Mr. Wood Whisperer who has a great video on using these kinds of bits... you can check out that video below

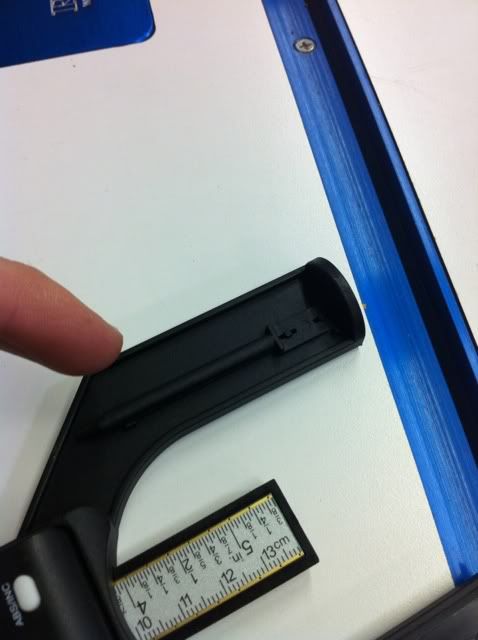

I had some scraps from my soon to be routed door frames and planned them to the same thickness as my doors so I could make the scraps into setup blocks. Like Marc mentions it's important to mark which bit does what because it's EASY to forget and mess up your stock and of course if you're like me you're not made of money and having to run across town for "one more piece" of hardwood sucks especially when it's avoidable.

So here are a few pics of the setup blocks I made and their corresponding marks on the bits.

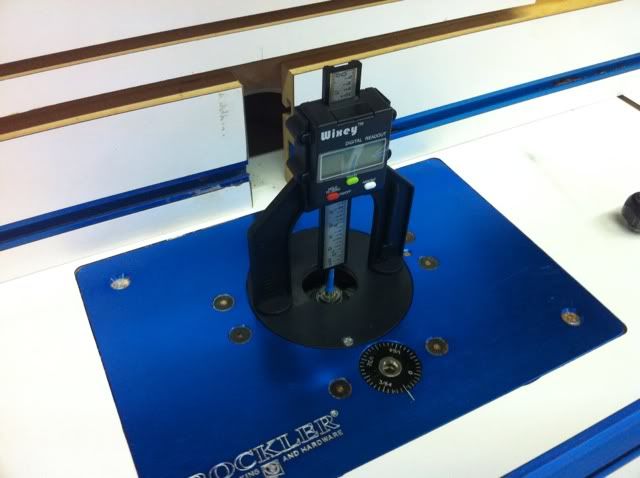

Getting this process down was a bit time consuming but once I had it down all went well. One thing to note when setting up your router for these jobs, since these bits may be a bit heavier than some of our other standard bits I found my router mount had worn a bit over time and during the start-up of the but the height adjusted on me. So make sure you have your router mount tuned to hold your heights tightly without movement when the bit spins up and vibrates the mount.

I'll post some follow up pics of my milled up doors before I glue them up the joinery turned out awesome and I will definitely be using these for more projects!